On 31st May 2024, over 20 participants had the opportunity to build on their industry knowledge and learn how additive manufacturing (AM) and 3D printing could potentially transform operations in the maritime sector. YEG members are young executives from our member companies who are under 45 years of age.

AM specialists from the DNV Technology Centre shared about the scale and complexities of 3D printing, and its potential to reshape maritime operations. One way in which AM technology could drive operational efficiency is by enabling on-demand production of complex parts and components directly onboard vessels or at remote locations, thereby reducing downtime and logistical challenges.

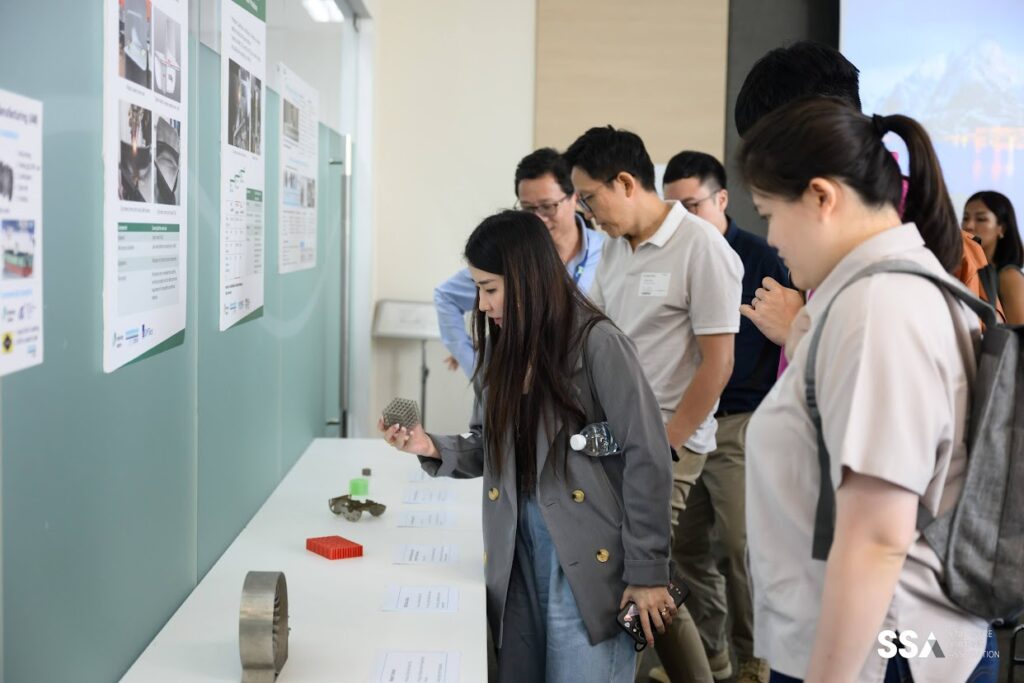

Furthermore, participants were treated to practical demonstrations showcasing the capabilities of AM in maritime settings. From the creation of lightweight, durable parts to the possibility of printing stainless steel components onboard vessels, the event highlighted AM’s versatility and its potential to transform shipbuilding and maintenance practices.

Vinod Kumar, IT Systems Administrator at d’Amico Shipping Singapore Pte Ltd highlighted the operational benefits of additive manufacturing (AM). He remarked, “3D printing can make complex, custom parts in one step with very little waste. This efficiency contrasts sharply with traditional methods, which involve multiple steps and significant material wastage.” He emphasised the potential for cost savings and accelerated production, particularly in enabling the rapid replacement of critical parts during vessel operations.

Takahiro Nunokawa, Assistant Manager at IINO Singapore, further underscored the impact of AM on reducing delivery times. “The reduction in delivery time could be a game-changer, given the fluctuations in the freight market,” he said. This significant advantage is crucial in the dynamic shipping industry, where timely access to parts can be pivotal.

Challenges and Opportunities

While the potential benefits of AM in maritime are vast, several challenges remain. These include ensuring the reliability and safety of 3D-printed components, navigating regulatory frameworks for certification, and managing the upfront costs associated with adopting new technologies. Discussions at the event highlighted the need for collaborative efforts between industry stakeholders, classification societies, and regulatory bodies to address these challenges effectively.

Amanda, Assistant Operation Manager at IINO Singapore Pte Ltd said: “One significant challenge lies in ensuring that onboard 3D-printed equipment meets class certification standards. Would vessels need to visit a port for certification, or could remote certification suffice? These questions underscore the need for clear guidelines regarding the classification of equipment fabricated by certified 3D printing machines.”

Singapore, a regional hub for maritime innovation and a gamechanger

The impressive facilities at DNV’s Singapore location, equipped with state-of-the-art testing machines is a testament to Singapore’s regional leadership in testing and certification capabilities.

“Through DNV’s comprehensive efforts that extend beyond operational improvements to encompass standardisation, quality assurance, research and development, educational initiatives, regulatory support, pilot projects, and stakeholder engagement, we’re creating a robust framework that ensures the safe and effective integration of AM across diverse industries, including maritime,” Vinod Kumar said.

In 2019, the Singapore Shipping Association embarked on a joint industry feasibility study to explore the potential of Additive Manufacturing (AM) when applied to marine parts. The primary objective of this initial study was to assess how AM technology could be integrated into maritime applications, laying the groundwork for future advancements. The progress since then is promising, reflecting how initial studies has evolved into a more developed and practical application of AM in the maritime industry today.

“Attending the event was enlightening. The focus on additive manufacturing’s potential to streamline operations resonates deeply with our day-to-day challenges in fleet management.”

Vinod Kumar, IT Systems Administrator, d’Amico Shipping Singapore Pte Ltd